Biofuel

The Cherepovetsles Holding company sawmills are continuously being improved and modernized. Due to increasing sawmill production output the amount of wood waste has increased. In order to maximize its processing, a fuel pellets production workshop was built at the Belozersky LPH sawmill in Nizhnyaya Mondoma village.

The pellet workshop is designed to produce up to 30,000 tons of products per year. The fuel pellets production let to minimize the unprocessed wood waste volume and improve the environmental situation. A significant part of biofuels is exported to various regions of the globe.

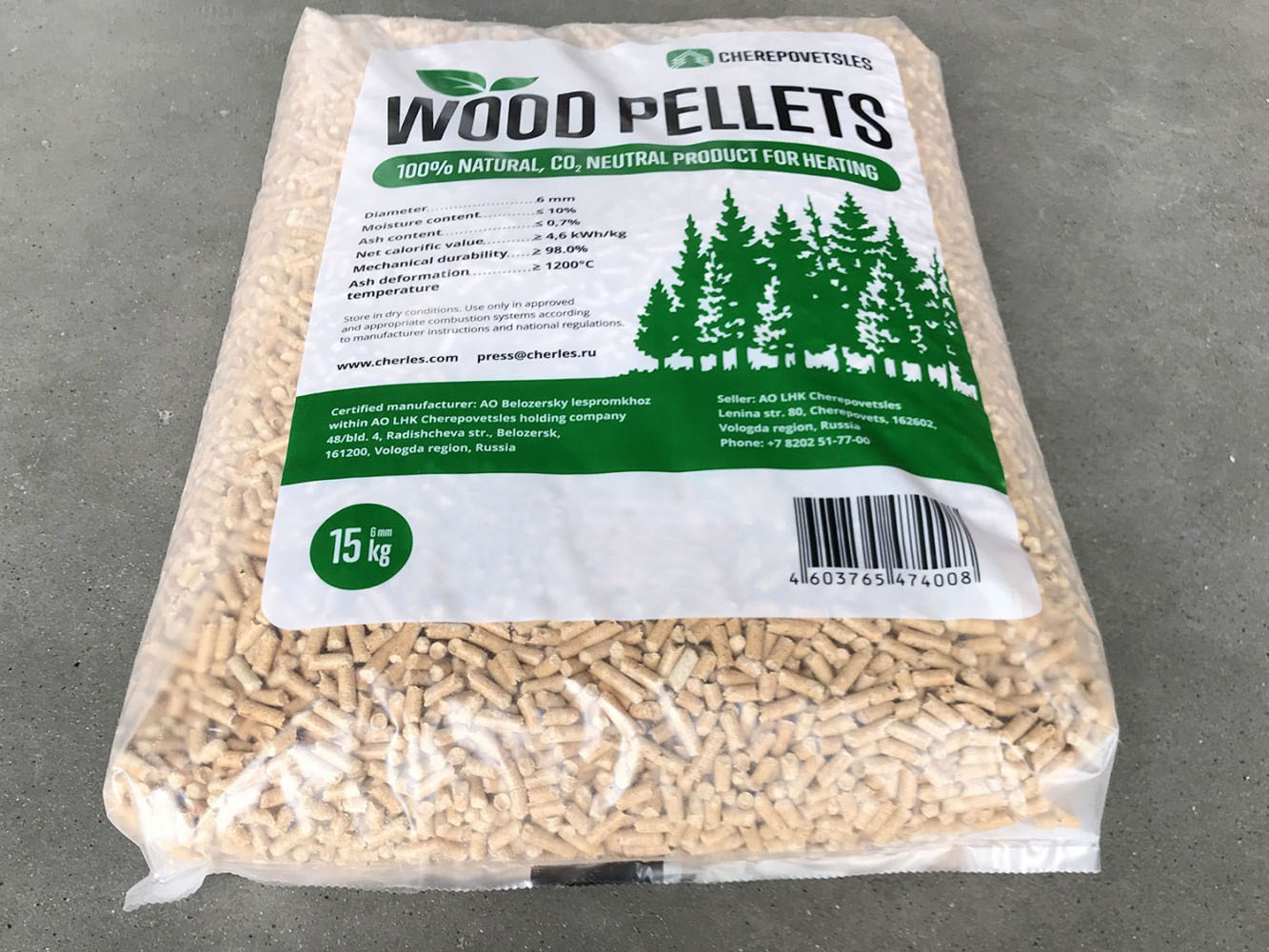

Specifications

- Diameter

- 6 mm

- Length

- 3.15 < L < 40mm

- Bulk density

- 600 - 750 kg/m3

- The lowest heat of combustion

- ≥ 4.6 Kilowatt-hour/kg

- Humidity

- ≤ 10%

- Ash content

- ≤ 0,7%

General information

Wood pellets are an eco-friendly, renewable energy source. The raw material for the pellets production is pressed, finely ground dry wood waste (sawdust, shavings and wood chips

The final product is wood pellets (from chemically untreated waste after coniferous sawn timber production without bark), OKPD2 code 16.29.14.192, GOST 33103.1-2017 "Solid biofuel" , HS code: 4401310000. Raw materials composition: 70% spruce, 30% pine.

The main qualitative characteristics of pellets are confirmed by laboratory analysis.

Wood pellets are used both by private households for space heating and by industrial customers (at thermal power plants) for the heat and electricity production.

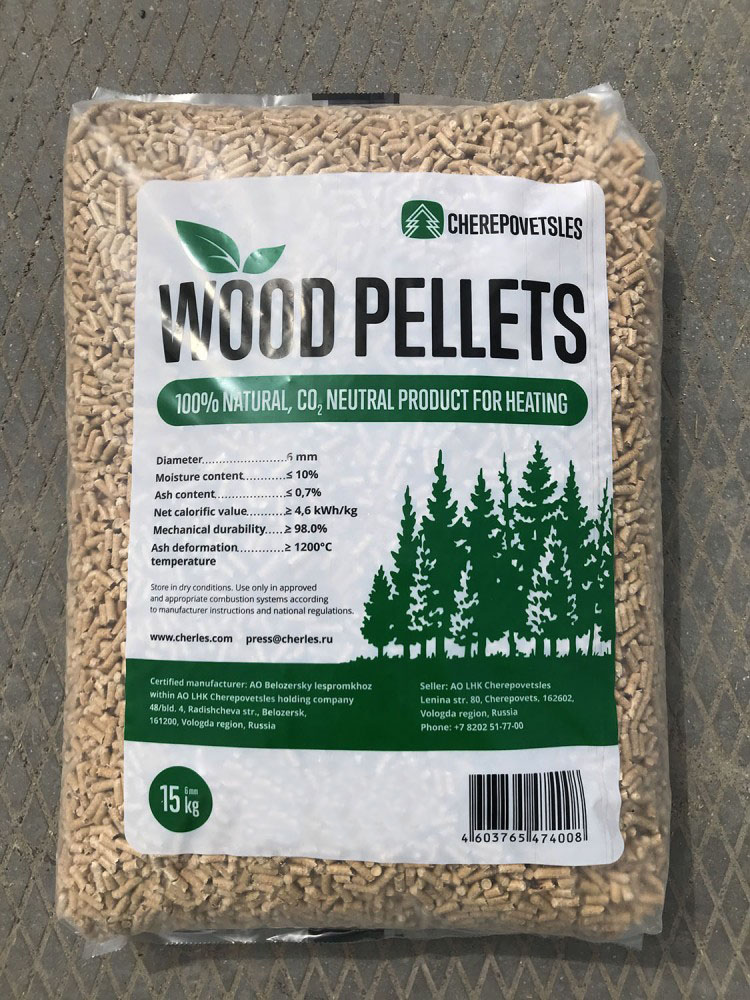

The main method of pellets shipment is big bags or 15 kg bags on a wooden pallet by trucks and containers from the sawmill warehouse.

The main method of packaging in design 15 kg polyethylene bags (buyer’s design is possible). Also packing wood pellets is big bags.

The pellets quality meets the highest requirements of European standards.

In October 2019, pellets workshop was put into operation at the base of AO Belozersky LPH on the production zone of Nizhnyaya Mondoma village sawmill in the Belozersky district of the Vologda region.

A complex technological line of "Amandus Kahl Gmbh & Co. KG" (Germany) company, as well as an automatic pellets packaging machine with on-pallet laying by "Robotika Kogler" (Slovenia) company is installed in the workshop.

The pellets production required more heat energy. The construction of a new boiler house at the sawmill allowed to reach full production capacity of pellet workshop - up to 30,000 tons per year.

The pellet production geographical location allows us to ship products to Europe and Asia markets.

Cherepovets city, 80 Lenina st.

weekdays from 8:00 till 17:00